YOUR PARTNER IN

PLASTIC PARTS MACHINING

Expertise in plastic machining

With over 30 years of experience in plastic machining, right in the heart of the Arve Valley, MANTI, a company integrated into MINESCO workshops since 2023, has established itself as a benchmark in micro-turning of high-precision plastic parts for assemblies and subassemblies.

Thanks to recognized expertise and a constant commitment to quality, we meet the needs of small and medium series in plastic machining, even for the most demanding applications.

Our flexibility and ability to adapt enable us to align with the expectations and rapid evolution of technological markets, ensuring unmatched responsiveness and performance.

Application Areas

Application Areas

We operate in various demanding sectors for micro plastic machining, such as:

Thanks to our technical mastery, we manufacture innovative products that comply with the strictest standards in terms of reliability, quality, deadlines, and costs at every step of the Supply Chain.

Methods Office : Innovation and Optimization

Our methods and R&D office transforms each client project into a precise and tailored finished product. We ensure:

- Study and adaptation of plans: Validation and optimization of designs to guarantee feasibility, cost reduction, and adherence to technical requirements.

- Development of specific tooling: Creation of bespoke tools (tool holders, cutting tools) to maximize precision and productivity.

- Process optimization: Development of operating ranges and continuous improvement of production cycles to guarantee performance and flexibility.

- Research and innovation: Integration of new technologies and materials to meet the needs of the most demanding sectors.

This synergy between methods and innovation allows us to guarantee impeccable quality and optimal support for our clients.

Machine Park

Technology Serving Precision and Performance

Our workshop is equipped with a cutting-edge machine park, carefully selected to ensure optimal production of our plastic machining, whether for simple series or complex parts. This combination of modern equipment and efficient processes allows us to precisely meet the diversified needs of our clients.

With our machines, we have the capacity to innovate and meet the demands of the most challenging sectors, where precision and reliability are paramount.

CN Tornos DECO 10, DELTA 12 et DELTA 26

Our numerically controlled sliding head machines offer advanced performance for productions demanding high precision. Our equipment is perfectly suited to manufacturing complex and delicate technical parts, particularly for demanding sectors such as aeronautics, electronics, and automotive.

Performance and Features

- Enhanced flexibility, ideal for small and medium series.

- Advanced functionalities enabling demanding machining operations, such as milling and tapping.

- Management of complex geometries, even for small dimensions.

- Optimal precision, essential to ensuring tight tolerances for the most delicate parts.

- Customizable configuration to meet the unique needs of each project.

- Increased productivity thanks to optimized setup times.

Tornos Cam Machines

Tornos cam machines represent an ideal solution for plastic machining in large series production of simple parts. This type of machine, with its compact design and great ease of use, offers numerous advantages:

- Reduced operating costs, enabling competitive pricing.

- In-house maintenance, ensuring swift and effective servicing.

- Proven reliability, with the capacity to produce high-quality, defect-free parts while adhering to tight deadlines.

These features enable us to achieve high productivity, producing several million plastic parts per year while maintaining controlled costs for our clients.

Tornos Delta 12

A Performance-Optimized Workshop

The entirety of our machine park is housed in a workshop designed to ensure performance, quality, and efficiency.

This equipment allows us to produce nearly 8 million plastic parts annually, with an optimized pace of 3 to 4 setups per week per technician, covering around 900 references.

Since the acquisition by Groupe Perrotton in 2023, our production capacity targets 10 million parts, a milestone that will soon be achieved.

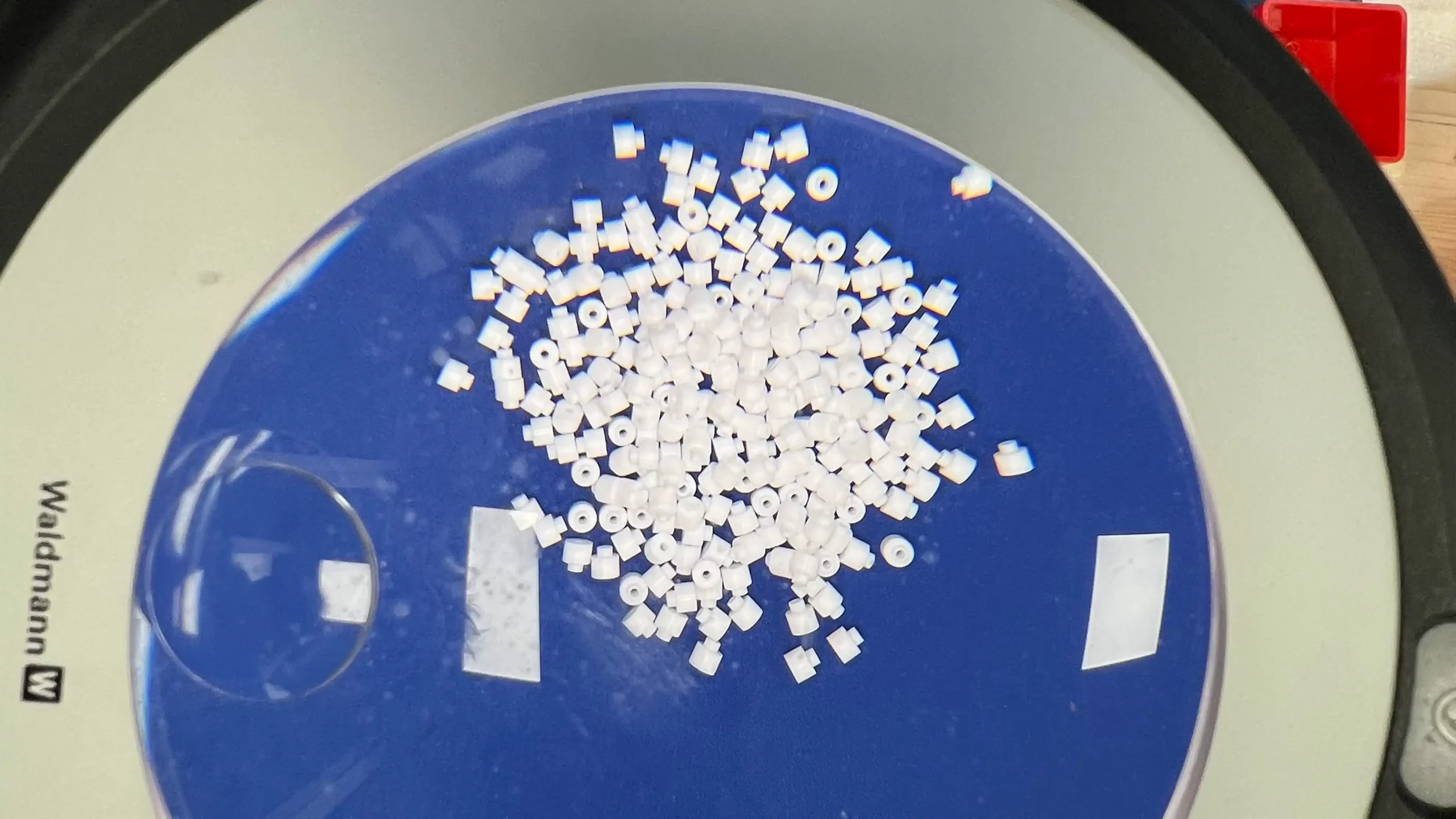

Mastery of Plastic Materials

Our expertise enables us to work with a wide range of technical plastic materials, each with unique properties suited to specific applications:

Applications :

Electronics: Cable insulators and electrical component insulation.

Aerospace: Connector insulators and protective materials for high-stress environments.

Aeronautics: Anti-friction components such as bushings or seals.

Applications :

Electronics: Connectors and electrical insulators.

Industrial: Moving parts (bearings, bushings) and structural components.

Consumer Goods: Household appliances.

Medical: Precise parts requiring high reliability.

Applications :

Medical: Implants or prosthetics.

Aerospace: Engine parts or casings exposed to extreme temperatures.

Industrial: Equipment components under mechanical stress.

Applications :

Electronics: Connectors and insulators for electrical circuits.

Industrial: Used in structural components and equipment requiring durability.

Aeronautics: Suitable for demanding environments, thanks to its robustness.

Applications :

Electronics: Connectors and insulators for electrical circuits.

Automotive: Wiring sheaths and protective insulation.

Applications :

Aerospace: Bearings, bushings, or lightweight structural parts.

Automotive: Components for high-performance gearboxes or pumps.

Instrumentation: Supports for measurement equipment under thermal stress.

Applications :

Electronics: Printed circuits resistant to high temperatures.

Medical: Devices requiring frequent sterilization.

Automotive: Assembly elements close to engines.

Applications :

Electronics: Housings for RF modules or sensors.

Medical: Components for imaging devices or sterilized equipment.

Aerospace: Insulators or electronic supports.

Applications :

Telecommunications: Antenna lenses, high-frequency component supports.

Instrumentation: Parts for precision measuring devices.

Electronics: Connectors or insulating parts.

We work with diameters ranging from 0.5 to 20 mm, with drillings starting at 0.4 mm. We also master advanced techniques such as milling, tapping, and cross drilling. Our skilled team leverages its expertise to deliver exceptional results.

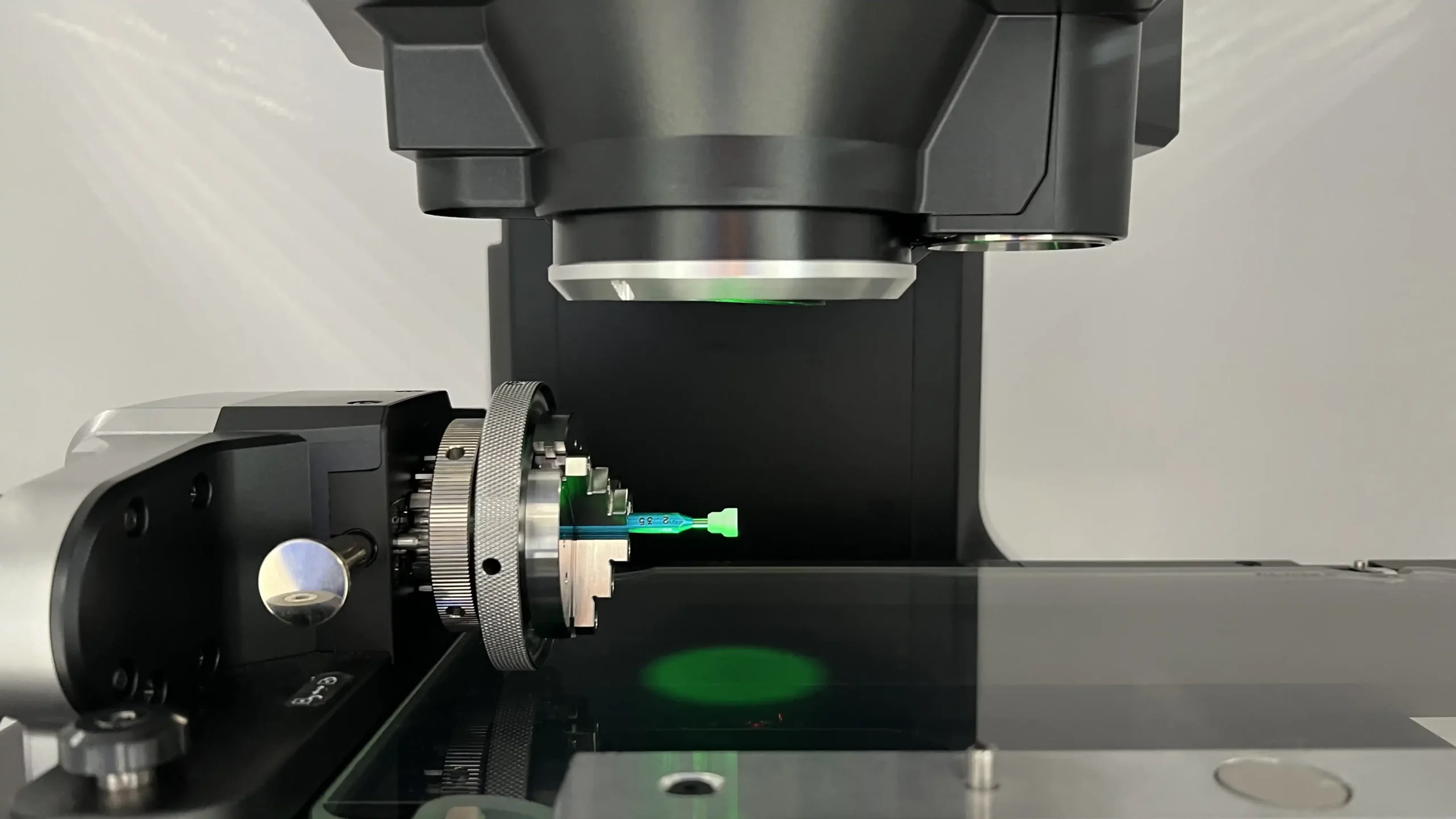

Quality Control and Durability

ISO 9001 certified, we place particular importance on quality through rigorous processes:

- Use of statistical methods (machine capabilities: cm, cmk; process capabilities: cp, cpk).

- Thorough unit inspection and sorting, performed manually and under binocular microscopes by experienced technicians to ensure maximum quality.

- Adherence to tight tolerances, especially in aerospace applications (minimum of 3 hundredths; PEEK 2 hundredths).

- Hot and cold washing of parts to ensure their stability.

Zero PPM is the goal we have set, and with 100% inspection guaranteed by a metrology department equipped with the best tools—Keyence devices, roughness meters, contour graphs, measurement columns, etc.—we are able to ensure full compliance of the produced parts, regardless of their technical requirements or specific tolerances.

Thanks to these state-of-the-art tools combined with the expertise of our skilled technicians, we identify and correct any potential deviations or variations in real-time. This rigor enables us to maintain a high standard of quality for our plastic parts, meeting the strictest standards of demanding sectors and fully satisfying our clients' expectations.

Furthermore, our processes include:

- Deburring and manual polishing, ensuring the perfect finish of our parts.

- Manual sorting of chips for recycling, maximizing their reuse.

By combining flexibility, adaptability, reliability, and tailored customer support, we offer high-precision solutions suited to the most demanding markets. Our commitment to quality and innovation makes MINESCO a trusted partner for your plastic machining needs.

Our references

MINESCO

Parc d'Activité du Pays Rochois,

210 rue de l'industrie

74800 La Roche sur Foron, France

Phone : +33 (0)4 50 97 74 10

CERTIFICATIONS

© Minesco 2023 - Mentions Légales – Politique de Protection des Données – Politique des Cookies - Co-réalisation BurtProd et Anaga